Share to

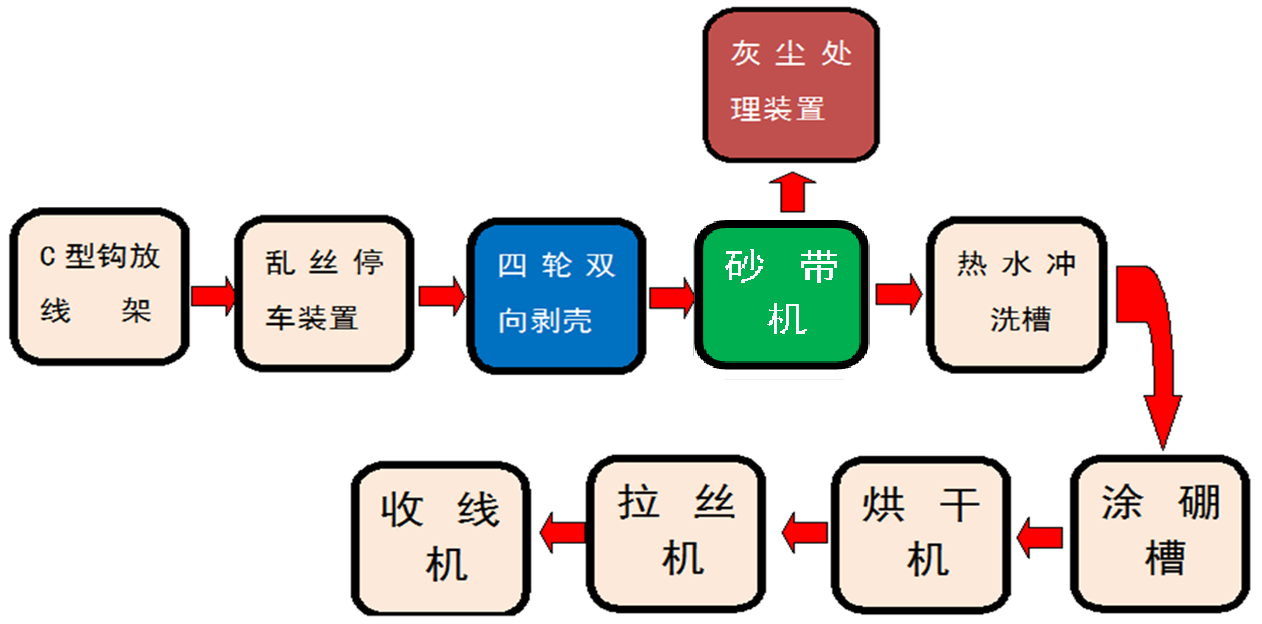

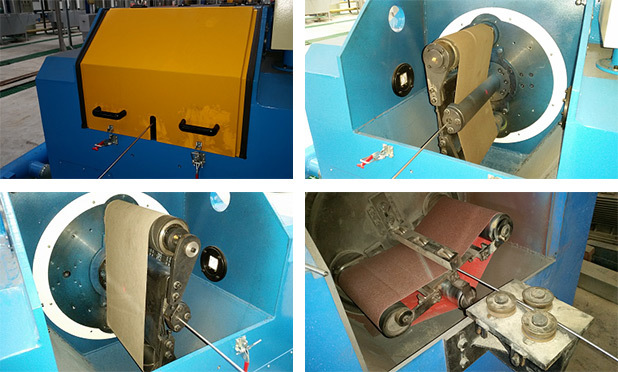

No pickling environmental protection surface treatment device

At present we have five main series of product:Wet drawing machine:LT250-550 reverse or no-reverse wet drawing machine.Dry drawing machine:LW350-560 block drawing machine:LZ350-600 straight drawing machine:LD 1/900-600 verticaI drawing machine.take up and pay 0ff:Φ 165-Φ 1400 spooler take up-pay off.coiler:SLl65-265:SGl65-1150 vertial、horizontal coiler or spooler iake up.

Product Description

Main technical parameters of the equipment

◆ Machining line diameter: 5.5mm-6.5mm

◆ The wire speed of the rod in the belt sander: the maximum 300m/min

◆ Spindle speed of the belt sander: 1440r/min Max

◆ Sand belt speed: Max. 1080r/min

◆ Sand-belt machine main motor power: 7.5kw

◆ Sand-belt motor power: 4KW

◆ Power of suction fan; 2 kw

◆ Sand-belt specification :80-160 mesh

No acid pickling environmental protection surface treatment equipment advantages

◆ High production efficiency

Compared with the intermittent surface treatment method, the application of pickling wire-drawing derusting machine replaces the traditional pickling, washing, coating, phosphating, saponifying, drying and other processes, the continuous production greatly reduces the production link, shortens the production cycle, reduces the production cost, and significantly improves the production efficiency.

The product quality is excellent

Because there is no residual acid or salt on the surface of the wire rod, it can avoid the problem of "hydrogen embrittlement" fundamentally, and the surface of the wire rod is free from oil after rust removal, which is beneficial to the cold drawing processing of the later process.

◆ Easy to operate

The derusting degree can be conveniently adjusted and controlled at any time in the production, and the instrument display is configured, which is intuitive, effective and quick, and it is not necessary to stop the experiment, which is conducive to timely quality control.

◆ Good environmental protection effect

Comprehensive cost is low: no acid, water and coal are consumed in the production; the environmental pollution caused by acid fog, waste acid and waste water is eliminated; the expenses of pollution control are saved; the workshop is clean and free from dust, which does not harm the health of workers; the production efficiency is high; the investment can be recovered after several months of use.

Related Products